BURIED deep in yards of Katan silk, a bitter Zeeshan stands and complains to his brother. He’s unhappy with the government, he’s unhappy with the business and he’s unhappy with the fact that they have to order silk thread from China in bulk.

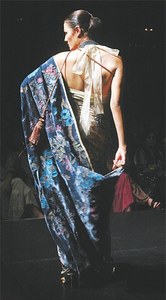

“You see this sari? Touch it, feel it. Rub the cloth against your cheek. Look at how the brocade and zari shine,” he said as he laid out a Mysore sari.

“They don’t make them like this anymore,” he said, stroking the fine cloth as he carefully unfolded the six yards. “This is what women used to buy in bulk for their trousseau, now we’re lucky if we sell more than one piece to a customer,” he added.

Take a look: Trends: In praise of the sari

Zeeshan runs his family’s business along with two of his brothers. He says he’s heard the story of how it started ever since he was five.

“My grandfather and his father before him started the business back in India when they used to live in Banaras — the hub of this tradition,” he said.

“We are just keeping that tradition alive. We are Ansari men, you see, this is in our blood,” he added.

According to the young shopkeeper, after Partition, his grandfather moved the family to Karachi and they had to start from scratch.

“When our family moved here from India, we were paupers. There was no market for Banarsi kapra here because everything was easily available across the border,” he said.

“My father, being the eldest of his 10 siblings, had to work in mills and factories till he could save up and buy a store here in Banaras Colony and call it Al Karim and Sons,” he said.

For a while, he said, business did well. “I remember my father telling us that it was normal to make Rs300,000 or more in a day. They used to be so busy at one time that they would have lunch after Maghrib prayers,” he said.

Then the violence started.

“Everyone was thirsty for blood then. I remember a time in the 90s when we were perpetual prisoners in our own home. My brothers and I couldn’t even go to school because of daily hungama (violence) and firing,” he said.

“The neighbourhood would be completely isolated in those days. There would be no groceries to go around as most of the shopkeepers would get their vegetables from Old Sabzi Mandi and rest of the household items would come from Jodia Bazaar. There wasn’t much one could do when everyone was scared to step outside their doorstep,” he added.

Till a few years ago, Zeeshan claimed, there had been incidents where personnel of law enforcement agencies or those engaged in ethnic violence would just open indiscriminate fire at anyone crossing invisible boundaries.

The situation didn’t get better, but at least people would still shop, Zeeshan explained. Now, he said, not many people want to travel so far away from the city’s centre. This has led many shopkeepers to provide door-to-door service, while some have also opened up shops in posh neighbourhoods like Zamzama.

Talking about business, Zeeshan said that they tried to promote family values and customer relationships. He added that they had customers who bought their wedding dress from his grandfather and now their grandchildren were buying from him.

Today, he said, a pure Banarasi sari in Banaras Colony costs Rs7,000 and above. “The most expensive one we have is a Mysore sari for Rs20,000-Rs30,000,” Zeeshan added.

Getting into the process of making a sari, he explained that first they sit down with their designers and sketch a pattern on an A4 size plain white paper.

“It is important to think of the blouse and pallu...also a good balance of traditional and modern design. Once this is done, then these patterns are sketched on graph paper and later developed into perforated cards,” he said.

Tariq, the designer, said that once the punched cards were ready they would be attached to a Jacquard loom or khadi , a device to simplify the process of manufacturing textiles with complex patterns as brocade, zari and mina.

“What’s important here is the thread which is imported from China for Rs15,000 per kilogram. If the government supports us even a little, it would be quite easy for us to make the thread here. All we need is the worms and they would do the rest,” he added.

“Our women are also a part of this process. Once the cloth is done, the material is taken to the women who sit together and cut the extra thread off to give it a neat look. This is what we call finishing,” he said.

Depending on the intricacy of its designs inspired from Mughal floral patterns, motifs, jhallar and mina work,a sari can take between 15 and 30 days and sometimes up to six months to complete.

Zeeshan hopes to take his grandfather’s business to new heights one day with shops around the world. “Our relationship with saris will never end. It’s in our blood. It is what our future generations will know and love too,” he said.

Published in Dawn, June 5th, 2018