Pakistan embraces zig-zag technology-led brick kilns to fight air pollution

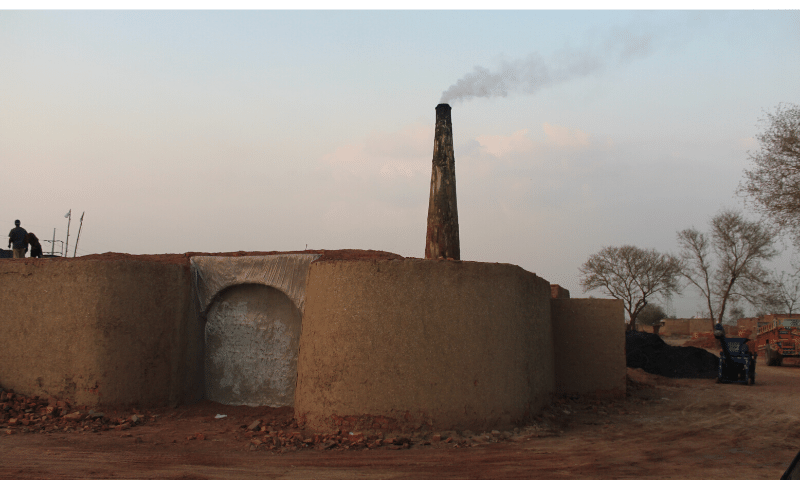

Haji Parvez has been in the business of brick kilns for the past 16 years. He owns a brick kiln in Raiwind on the bypass of Sue-e-Asal road. For 14 years, Parvez had a traditional brick kiln that was a Fixed Chimney Bull’s Trench Kiln (FCBTN) type and it was only in 2018 that he decided to convert it to the cleaner zig-zag technology.

He had his reasons for doing so. Previously, on the traditional brick kiln, Parvez couldn't enhance brick production. "The brick kiln had a maximum capacity of producing 30,000 bricks. On the other hand, through the smart zig-zag technology, I can easily enhance the production from 30,000-50,000 bricks daily."

Parvez says, "When one of my friends, Haji Islam installed the first brick kiln on zig-zag technology, I could see the benefits that he was reaping at low cost, and that motivated me to convert my kiln from traditional to zig-zag technology in 2018."

The conversion had cost Parvez over two million rupees but now the cost to convert has substantially reduced to one million. "The cost reduced as brick kiln owners engineered and introduced a fan/blower made of fiber glass that can withstand high temperatures," informs Parvez.

Difference between traditional and zig-zag technology-driven brick kiln

The real difference between the traditional Fixed Chimney Bulls Trench Kiln (FCBTK) and the zig-zag technology driven brick kiln is that in the former the placement of bricks is done in a straight pattern, whereas in the latter the bricks are placed in a zig-zag pattern. The zig-zag pattern allows to efficiently manoeuvre the air for heating purposes.

Furthermore, the black soot that comes out of the traditional brick kiln is due to inefficient burning of fuel, whereas, the zig-zag setting of bricks and continuous feeding of small quantities of coal improves fuel efficiency. As a result, the emitted smoke from the kilns employing zig-zag technology is white coloured and with significantly low air pollution levels. The Induced-Draught zig-zag kiln type also has a fan, which allows to control the air, thereby making the coal burning process even more efficient.

There is also a strong business case for converting to zig-zag technology. It reduces coal consumption by 20 per cent, carbon emissions by 40-60pc, produces more A-grade bricks, and brick production can be enhanced as well, says a research by the International Centre for Integrated Mountain Development (ICIMOD), a regional intergovernmental organisation working in the Hindu Kush Himalayas as part of the UN's Climate and Clean Air Coalition (CCAC) initiative. The organisation was also the first to bring the idea to introduce fuel efficient brick kilns running on zig-zag technology to Pakistan.

The CCAC initiative aims to improve the climate and air quality, and removing Short Lived Climate Pollutants (SLCP) from the atmosphere, with a focus on the brick-making sector.

In this regard, the ICIMOD, being the lead partner for the CCAC Brick Initiative, helped implement cleaner brick production in Pakistan, India, Bangladesh, and Nepal by working with the governments as well as the private sector in the four countries. And although Tunnel Kilns are the cleanest technology to-date when it comes to brick production, due to the high construction costs involved and complex operations, zig-zag technology was deemed a more viable option in Pakistan.

Bidya Banmali Pradhan, who heads ICIMOD's Air Pollution Solutions Programme, highlights the benefits of zig-zag technology vis à vis the Fixed Chimney Bulls Trench Kiln (FCBTKs). "The brick kilns running on zig-zag technology consume 20pc less coal, emit 40pc less particulate matter (PM), and 60pc less black carbon," she says. Black carbon is a potent climate warming component which is a major contributor to global climate change, possibly second only to carbon dioxide.

Pradhan explains that in zig-zag technology, the fireman would feed coal in small quantities in the kiln in a Z-pattern continuously. "The (black) soot that earlier used to come out through the chimney in the traditional brick kiln is fully burnt in the zig-zag technology-driven brick kiln. The smoke therefore is white in colour."

"Not just that, due to improved combustion and uniform heating, more A-grade bricks are produced," adds Pradhan.

Good for business

However, introducing zig-zag technology-driven brick kilns in Pakistan wasn’t an easy task, Pradhan shares.

"We visited Pakistan in 2017 and met the officials of the National Energy Efficiency & Conservation Authority (Neeca) and the All Pakistan Brick Kiln Association. We convinced the brick kiln manufacturers that converting to zig-zag technology was in their best interest and told them that it would also benefit the environment."

"We hosted some of the brick kiln owners in Nepal in 2018 and showed them the technology. The first brick kiln on zig-zag technology was successfully constructed the same year by Haji Islam, who is an active member of the All Pakistan Brick Kiln Association," she says.

Muhammad Shoaib Khan Niazi, president of the All Pakistan Brick Kiln Association, was also part of the delegation that visited Nepal to witness the technology. Upon their return from Nepal, the ICIMOD also organised training sessions for brick kiln owners and workers.

Niazi says the brick kiln association fully supports zig-zag technology, "as it makes an excellent business case".

"The return on investment can be achieved within a short period," he adds.

Owing to the smog crisis in winters, the Punjab government does not allow traditional brick kilns from working in September and October every year. Because of this, Parvez says, "until 2018, my traditional brick kiln had to be shut down too, resulting in losses of millions of rupees. Not only could I not do any business during these months, but when I would restart the kiln in November, the preheating of the kiln used to cost me approximately one million rupees."

"That ordeal is over now, as my brick kiln on zig-zag technology runs throughout the year," he shares.

Parvez highlights the benefits he is able to mint by shifting to the cleaner technology. "On every 1,000 bricks, I am now able to save Rs400-600. The monthly consumption of coal has gone down from 200 tonnes to 160 tonnes."

Zig-zag technology has received a positive response from brick kiln owners in Punjab.

"We are now approaching the provincial governments of Sindh, Balochistan, and Khyber Pakhtunkhwa, so they can also benefit from this technology. Imagine if we are able to reduce up to 60pc of our emissions from the 16,000 brick kilns across Pakistan," Pradhan says, adding: "It will be a fantastic opportunity for Pakistan to refer to this achievement in the country's Nationally Determined Contributions (NDCs), as part of its commitment to the Paris Climate Agreement."

Niazi is also hopeful that zig-zag technology will gain momentum in the country as it makes more sense for business as well.

"We have convinced our fellow brick kiln owners in Khyber Pakhtunkhwa, Balochistan, and Sindh to replicate this technology, and our trained labourers are ready to play their role as well."

For this, trained labourers working in zig-zag technology-led brick kilns in Punjab would go to other provinces to train the labourers working there, so that they can learn how to produce bricks through zig-zag technology.

Niazi is hopeful that ICIMOD can convince the provincial governments to speed up the transition.

International support to transform brick making sector

International support can be instrumental in converting these brick kilns to zig-zag technology. Pakistan has already applied for funding from the Global Environment Facility (Gef) to transform the country's brick kiln industry to one that is more environment-friendly and within a period of five years.

"If Pakistan is able to receive this funding, it would help revolutionise the entire brick kiln sector by converting it to the zig-zag technology. Few tunnel kilns would also be constructed as part of this project," Pradhan says.

Haji Parvez and Haji Islam say that while the Punjab government had initially agreed to support them financially in constructing the initial prototypes for zig-zag, no such funding was disbursed to them, and nor were they given any loans at flexible rates for the purpose.

Meanwhile, the 2018 Smog Commission Report acknowledged that the environment protection department of Punjab would provide 'subsidy support' to brick kiln owners to convert to the more environment friendly zig-zag technology.

Naseem Ur Rehman, the director of Punjab's environment protection agency (Epa), says that Dr Parvez Hassan, chairman of the Smog Commission, had requested the State Bank governor to provide soft loans to brick kiln owners at flexible rates.

"Governor State Bank has approved the idea of issuing soft loans at 6pc interest rate to brick kiln owners so they may convert to zig-zag technology under the Small Medium Enterprises (SME) programme," says Rehman.

Rehman says the federal cabinet has also discussed the possibility of offering financial support to brick kiln owners for conversion to zig-zag technology, adding that further deliberations have been paused since the Covid-19 outbreak in Pakistan.

Punjab's 2020 ultimatum

The Punjab government has also gone one step further. Rehman says that "by the end of 2020, all polluting brick kilns in Punjab must convert to zig-zag technology or else they would be shut down indefinitely".

The transition from Fixed Chimney Bull's Trench Kiln (FCBTK) to zig-zag technology is finally gaining momentum and the provincial Epa confirms that in Punjab 592 brick kilns are already running on it.

Haji Parvez is on the winning side, as he is able to produce A-grade bricks at a lower cost and that too with much more controlled impact on the environment. For others, it is only a matter of time before they can recognise the benefits of zig-zag technology and decide to adapt. Failure to do so could mean that they may no longer be able to function.

Air doesn't respect borders and in South Asia, the brick kiln industry remains one of the major contributors to air pollution. Zig-zag technology offers hope by reducing the harm caused to the environment and the air, which is currently laden with life-threatening pollutants and particulate matter.

People living in our part of the world have reduced life expectancy by an estimated average of a year and seven months due to high exposure to PM2.5 pollutant, according to the State of Global Air 2019 report.

The real challenge however still lies ahead — to transform the 150,000 brick kilns in all of South Asia. Though it's a long way before we can achieve that goal but it's among some of the critical steps that have to be taken so we may save millions of lives that are at risk from air pollution.

Syed Muhammad Abubakar is an environmental journalist. He tweets @SyedMAbubakar and can be reached via s.m.abubakar@hotmail.com