J.B. Industries is a vertically integrated manufacturer and exporter of knit, fabric and apparel. It is a sister concern of the Bilwani Group of Industries, which has two other units — Mustaqim textile processing and Bonanza — that manufacture readymade knitwear and woven garments.

The unit has a capacity to process 25,000kg of dyed fabric and 8,000 metres of printed fabric per day. The apparel division is capable of producing 0.5-1m garments per month, depending upon the style and fabric.

The company also exports all kinds of knit fabric, ranging from solid-dyed and yarn-dyed to printed all-overs, to its customers in 15 countries around the globe.

The government keeps raising the cost of doing business every now and then, and even viable units sometimes close down

Established in 1992 it is an off-shoot of Mustaqim Industries, the company operates independently and caters to the needs of local and global brands such as Tesco, Next, Asda, KIK, Kohl’s and Wal-Mart etc.

It is a green company which focuses on eco-friendly manufacturing with an active policy to reduce carbon emissions by using state-of-the-art machinery and equipment.

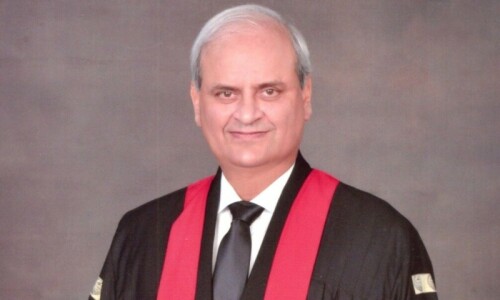

Talking to this writer in his factory office in SITE, Mohammad Jawed Bilwani, who owns the company, said the unit’s standard operating procedures (SOPs) are designed to conserve energy and recycle water and waste material.

Giving some details on measures adopted by his company to conserve energy and to face the challenge of the ever-rising cost of doing business, he said the heat emitted by the unit’s power generator is diverted to the boiler. The boiler then makes steam, which is used in the processing of fabric and thereafter cooled down through a radiator, which converts it back to water.

Similarly, for lighting, all tube-lights have been replaced with surface mount devices (SMDs), which are an improved version of traditional LED lights and save more energy.

The unit recycles all its waste in one way or the other, and uses dyes and chemicals that are free from all banned ingredients. To keep costs in check, the unit is also equipped with latest dyeing machines that have a very low liquor ratio. The ratio used to be 1:20, but has now been reduced to 1:4.5, which also saves chemicals.

Rising costs of energy, labour, water etc are forcing industries to keep enhancing their production and exports by at least by 20pc, he maintained.

The government keeps raising the cost of doing business every now and then, and even viable units sometimes close down. It is time that the government looks at this issue seriously, as without sufficient margins the industry cannot go for balancing, modernisation and replacement (BMR).

Mr Bilwani suggested that the government provide technical support and create awareness about efficiencies and conservation of energy and other industrial inputs.

Talking about issues facing the country, he said the biggest problem is the huge and persistent trade deficit, which is keeping the economy dependent upon the IMF and other foreign donors.

The only way out, he feels, is to give priority to export-oriented industries. And industry as a whole should get a priority in the supply of utilities like power, gas and water; for this, dedicated pipelines should be given to industrial estates.

He regretted that the government is ignorant about the number of export-oriented units that have closed down owing to a loss of competitive edge.

Citing an example, Bilwani said there was a time when local polyester filament yarn manufacturers were catering up to 70pc of the need of the domestic textile industry. The situation has now reversed as many units have closed down.

Even though it is blessed with the cotton crop, Pakistan lags behind in textile exports against regional countries, including Bangladesh, where the cotton crop is not cultivated and its entire demand is met through imports. And Bangladesh earns $6bn by converting 1m bales into value-added products like garments and home textiles etc. Against this, Pakistan earns only $1.7bn per 1m bales. On average, Pakistan produces 13m bales annually.

However, the country’s annual textile exports are low at $13.73bn, against total exports of $25.13bn. And given the huge import bill of $45.11bn, this leads to a massive trade deficit. The government would only have to take steps to remove distortions and ensure competitiveness with regional countries.

All of this is possible if the government ensures uninterrupted supplies of utilities, at rates prevailing in the region. Labour holidays for the export industry should be fixed for each year, and adjustments should be allowed against sudden closures on account of strikes etc.

The availability of raw materials for the value-added textile sector should be ensured at competitive prices so that the end products could easily compete in the international market.

Bilwani also asked the government to encourage cotton growers, and in case of a bumper crop, they should be compensated if prices crash. It should also give premium prices to farmers who grow uncontaminated cotton.

Published in Dawn, Economic & Business, March 23rd, 2015

On a mobile phone? Get the Dawn Mobile App: Apple Store | Google Play

Dear visitor, the comments section is undergoing an overhaul and will return soon.